Solar Charge Controllers for Oil & Gas

Why Morningstar?

Morningstar is the leading brand and first choice of solar professionals designing off-grid powering systems for the Digital Oilfields of today and tomorrow, for one reason: with over four million Morningstars installed in the field since 1993 in over 100 countries, there’s no brand in the solar industry more proven for reliability in the harshest environments. With Morningstar, oil and gas and other industrial users around the world can use efficient, reliable, and cost-effective solar electricity to remotely power their essential systems on-site, greatly improving both economics and safety.

HazLoc Certified

Out of a field of over 700 brands of charge controllers, Morningstar is unique for earning HazLoc certification on a wide range of models. For months, the company underwent a rigorous audit of its operations, documentation, and quality procedures in the design, control, and production of these solar charge controllers. Achieving certifications for HazLoc use in North America (with UL/CSA ratings), and passing the Quality Assurance Notification for ATEX, and Quality Assurance Registration for IECEx, demonstrates that Morningstar follows rigorous standards and procedures to ensure quality and consistency in its product lines. Morningstar’s new range of HazLoc controllers makes it possible to enable “digital oilfields” with larger (up to 1,100 Watts), more capable solar electric solutions.

The Class I Division 2 Group A-D Hazardous Locations where select Morningstar solar charge controllers have achieved certification are defined below:

| Class I | Division 2 | Group |

|---|---|---|

| Gases, Vapors, & liquids | NOT normally present in an explosive concentration (but may accidentally exist) |

|

Morningstar has achieved all necessary UL/CSA (North America) and IECEx/ATEX (International and European) certifications for ProStar™, ProStar MPPT™, SunSaver™ and SunSaver MPPT™ products.

Need Help with

Solar For Your Oil and Gas Applications?

If you aren’t sure which option would work for you, use our contact form to request a consultation with one of our staff who will recommend the right products. You can also use our how-to-buy form to request specific products from our inventory.

Recent Oil and Gas Projects

As Seen In

Starting in July, Morningstar introduced our new North American and International hazardous location (HazLoc) certifications to the global press. This outreach covered Oil & Gas, Power & Energy, Environmental and General Business publications in North America and selected regions around the world. Over 150 publications carried the news, including the high-profile ones below:

As spending increases and oil companies expand their operations, their equipment assets become more widespread. This requires a scalable, convenient and effective means of centralized management, now referred to as the “digital oilfield”. Because this requires secure local and remote monitoring capabilities through a modern, complex network incorporating Ethernet switches and wireless access points (WAPs), SNMP is a common requirement for these systems.

SNMP makes device setup simpler, and provides universal protocol support across many types of networking equipment and IT management systems. With the added versatility to store data onsite or in the cloud, users of an SNMP-based system have the ability to choose how their data is managed and protected.

This is why Morningstar has integrated Simple Network Management Protocol (SNMP) into its products. An open standard IP-based protocol, SNMP works with selected Morningstar products in conjunction with Morningstar’s Ethernet MeterBus Converter (EMC-1) communication gateway. As Oil & Gas operators increasingly turn to solar electricity for powering various systems, Morningstar solar components are better equipped to meet their needs.

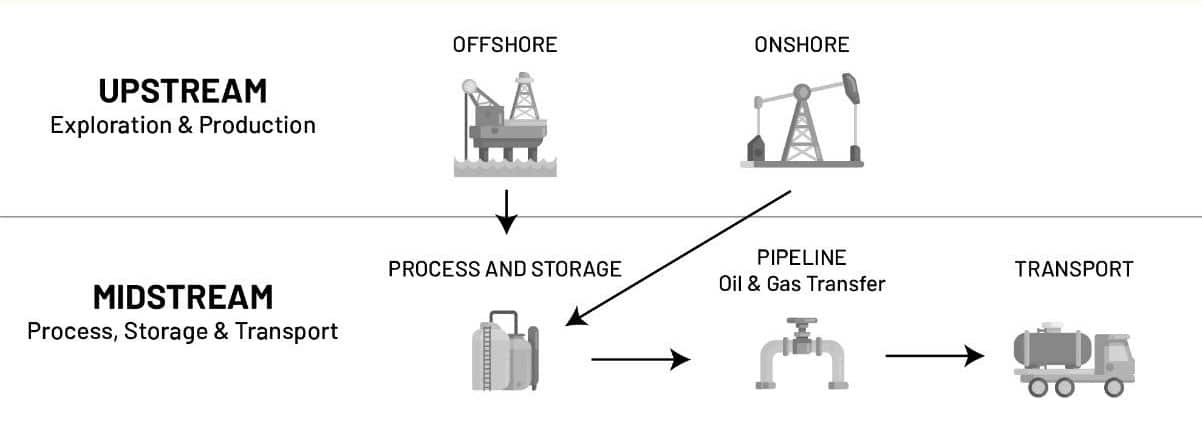

Off-grid solar power is used at upstream and midstream oil and gas operations

Typical Oil and Gas solar electricity applications

- Remote telemetry (RTU)

- Seismic equipment

- Remote measurement

- Cathodic protection (using DC current to help prevent pipeline corrosion)

- Valve control

- Injection pumps

- SCADA equipment

How It Works

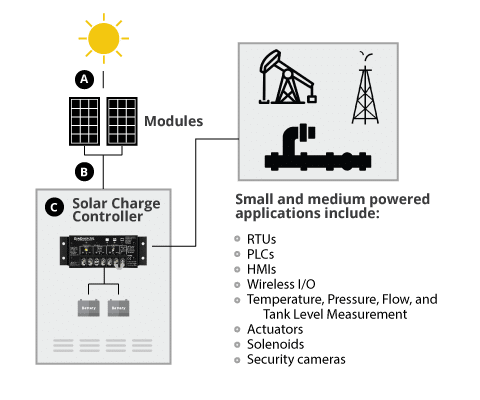

Small and Medium Solar Powered Applications

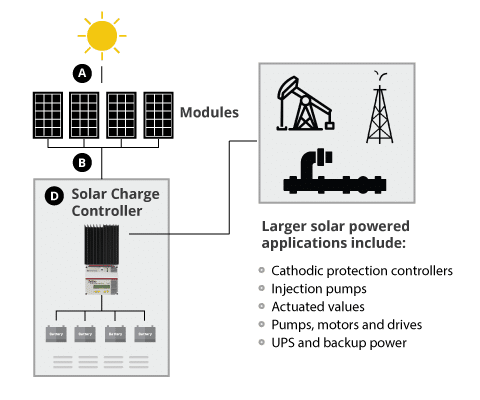

Large Solar Powered Applications

During the Day:

Solar modules or panels convert sunlight into DC electricity which flows into a charge controller. The controller:

- Optimizes solar “harvesting” from the panels (if equipped with MPPT technology)

- Regulates and safely charges the batteries

- Powers DC-operated loads if equipped with load control (if there are AC loads present, the system will also include a DC-AC inverter)

During the Night:

The solar charge controller keeps working—by preventing any “reverse current” flowing from the batteries to the PV modules, and (if equipped with load control) disconnect power to the loads if the battery voltage dips too far, which can quickly kill batteries.

Additional Resources for Oil and Gas Solar

Remote Critical Power for the Digital Oilfield: Using Solar in Hazardous Locations

The Morningstar Team presents off-grid solar solutions for oil and gas sites during this webinar hosted by North American Oil & Gas Pipelines.

The Solar Powered Industrial Systems guide contains over 35 pages of information, including application and product photos from some of the most extraordinary off-grid sites around the world.

Features & Benefits

- Tested to lab-recognized hazardous environment certification for installation near or in Class 1 Division 2 operating zones, as is generally required in oil & gas applications

- Maximum Power Point Tracking (MPPT) technology to extract every bit of electricity possible from the solar source, by converting extra voltage into useful amperage. Morningstar MPPT controllers have industry-leading TrackStar technology on-board for that purpose.

- Industry-leading technical support from a US-based company.

- Load control for easy system integration.

- Support for industrial-standard networking, monitoring and communications protocols including MODBUS, MQTT and SNMP, when used with Morningstar’s Ethernet MeterBus Converter (EMC) accessory.

- Data logging to record charging/load Amp-hours and alarm/fault notifications.

- Full programming to enable a high-level of system customization.

- Built-in communications and diagnostics capabilities

- Temperature charging protection and advanced charging algorithms to protect expensive storage batteries, both lead-acid and advanced types including lithium. Dead battery recovery feature helps reduce system down-time.

- Designed for trouble-free operation in extreme temperature and weather conditions. Epoxy-encapsulated circuit boards and 60C ambient temperature ratings to handle harsh environments including tropical, coastal and arid regions. Weatherized construction; no cooling fans to fail

- Simple, out-of-the-box operation and easy installation

- UL listing on most models

- Safety features built-in, including alarm/fault notifications, mis-wiring protection, lightning protection

© Morningstar Corporation